|

Union Process

Union

Process in USA is the

inventor of Attritors and has over 20 years experiences in the

production of

Attritors. Its equipments will provide you with high speed, high

efficiency,

super-fine grinding process and well-distributed dispersion. Moreover,

the

power consuming of the equipments and wear-and-tear for the machine are

also

very low.

Union Process devotes itself

to the development and improvement of the grinding equipment and their

main

purpose is to provide the most need equipment for customers in

different

industries, including Laboratory Mills, Production Mills, Dry Grinding

Attritors, Wet Grinding Attritor, Small Media Mills and etc.

The applicable field of this

kind of attritor is very wide, can be used in pigment, ink, toner,

ceramics,

metal and nonmetal, serving large number of famous customers worldwide.

The

technical experts and the professional lab of Union Process will

provide you

the optimal production program and also will recommend the optimal

machine to you.

‧Wet Grinding Attritor:

Vertical Batch Attritor

-SSeries

Vertical Continuous

Attritor

-C/H Series

Vertical Circulation Attritor-QSeries |

‧Small Media Attritor:

Vertical Small

Media Attritor -SDM

Horizental Small Media Attritor

-DMQ

|

‧Dry Grinding Attritor:

Vertical

Batch Attritor -

SDG series

Vertical High Speed Attritor

- HSA Series

|

‧Lab Attritor:

All

types

above have lab type attritor. The continuity is better

for

lab type proportionately enlarge to production type.

|

|

|

Vertical

Batch Grinding Attritor:

‧S Series:

The grinding process is batch type with inside circulation, can get

sample and check whenever necessary without turn off the machine. The

system that is used for protecting from metal ion pollution is also

provided. It is better applied to precise ceramic and electronic

ceramic industry with strict requirements.

‧SL

Series:

The “L” type arms with special design can prevent

grinding

the corners. It is better applied to milling magnetic material and

slice shape metal powder industry.

‧SC

Series: The design of taper milling is with high effective

and special for high-density materials such as tungsten carbide.

|

|

|

Vertical

Continuous Attritor:

‧C/H

Series: Continuous Attritor is a vertical type Attritor

used for

large-scale production. Pre-mix powder liquid is charged from the

bottom and discharged from the top. Advantages: continuous large-scale

production, high speed grinding and processing, excellent temperature

control, simple and safe operation system, less maintenance and power

consumption.

‧CL,

CLS Series: especially design for grinding lime

and limestone.

|

|

|

Vertical Circulation Attritor:

‧Q

Series: Circulation Attritor applies to material with

particle size of

1—100 micron that is hard to grind. Comparing with other

Attritors, large quantities of materials can be ground with a smaller

investment of grinding media and Attritor equipment.

The slurry can be monitored continuously during the grind. Additional

ingredients can be added to the premix tank at any time during the

grind, with sensitive materials being added near the end of the

grinding cycle, in order to maintain the efficiency of grinding and

same composition of materials.

It combines a main Attritor with a pregrind tank. The costs can

decrease, because the main Attritor needs less grinding media.

Meanwhile, the circulation makes final output reach narrower particle

size distribution and get high quality products.

|

|

|

Vertical

Dry Grinding Attritor

It is used for super-fine milling mechanical alloy and nonmetal

mineral, also can combined with classified machine.

‧SDG

Series: SDG Dry Grinding Attritors are ruggedly built

machines with

special designed, two-speed, high starting torques motors. They also

equipped with jacketed, stainless steel tanks and tilting devices for

ease of cleaning and maintenance. Cover seals can be provided for

conditions where dust control is desired, or where grinding must be

done under a closed inert gas system. Torque meter is available

including torque and speed sensor read-out.

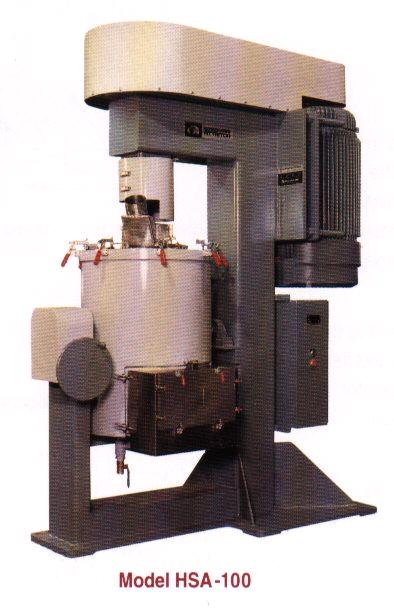

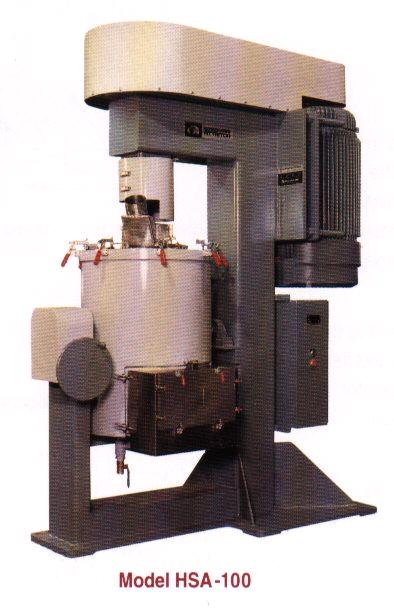

‧HSA

Series: HAS Series has a unique patented design concept

that includes a

new grinding tank internal configuration tank, which has a series

specially shaped agitating arm and diverted discs are mounted along the

longitudinal axis of the agitator shaft. This new engineering design

makes it possible to use smaller grinding media, operate at higher

shaft RPM, and increase residence time of processed material in the

grinding chamber to insure a finer grind.

|

|

|

Vertical

Small Media Attritor

Using mini media from 0.25 to 3mm can get sub-microns materials with

good particle size distribution.

‧SDM

Series: Vertical Small Media Attritor uses specially

designed shaft and

Delta Discs configured to accommodate small media milling, easy to

clean and narrow particle size distribution, it is best applied to

expensive ink, pigment, toner and nonmetal mineral (mainly heavy

calcium and claimed ceramic clay).

Other advantages as follows: No premixing requirement, Energy efficient

operation, Material can be inspected and additions made at any time

during the grinding cycle, etc.

|

|

|

Horizontal

Small Media Attritor:

‧DMQ

Series: It is UP’s newest Attritor application

that grinds with

unique process (grinding with forced centrifugal force) with high

efficiency and it is the most advanced Horizontal Attritor.

Other advantages as follows:

1.

Operates in either circulation or continuous mode;

2. Easily adjustable product discharge

openings

maximize throughput and accommodate grinding media from 1mm to as small

as 0.3mm.

3. Process materials to 0.1µm

with particle

size distribution around several microns, even to nanometers; this is

the highest level of physical grinding.

4. Special design of DALITA disc reduces

the shake of shaft and machine during milling.

5. Indexed discs provide directed and

uniform media distribution throughout the mill chamber.

6. Large, heavy-duty media separator

located at the end of the mill makes service fast and easy.

…<More

information about UP> |

|

|

|

|

|

|

|

Phone:+86-21-6145.7238

Fax:+86-21-6145.7239

Add:

Room 2506, No.1, Lane 600,

Tian Shan Road, Shanghai, China

Post Code: 200051

Looking

forward to meeting with you!

|

|

|